The Bay State has a long history as a manufacturing & construction center, including products impacting your everyday life

Worcester and Central Massachusetts have long been known for their exports, ranging from textile looms in the early-to-mid 1900s to medical devices and components for airplanes, rockets and spaceflight.

The Blackstone Canal, built in the 1820s, first made Worcester a hub of commerce when it allowed goods to be shipped to the city and down to Narragansett Bay in Rhode Island, said Timothy Murray, president and CEO of the Worcester Regional Chamber of Commerce.

Along with the Blackstone River, other waterways helped provide hydro power to dozens of factories and mills.

“The combination of geography and utilizing some natural assets in the region created that manufacturing base that then just grew,” Murray said.

After the canal closed after a few decades, then came the railroads, and Worcester became a crossing hub for New England. Again, the manufacturing industry in the region kept growing.

As technology has advanced and globalized occurred, the manufacturing economy now looks much different. Large brick mills or factories – an iconic staple of many small Massachusetts towns – were abandoned as jobs were shipped offshore, but the industry has diversified and advanced, bringing new jobs and new exports to the region.

The idea of manufacturing as a dirty, blue-collar, low-wage job is a thing of the past, said Murray, citing the rising prevalence of biomanufacturing, plastic manufacturing and medical device manufacturing.

“These kinds of advanced manufacturing have replaced and become a higher percentage of traditional manufacturing,” Murray said.

Although the products have largely changed, the core elements of manufacturing have stayed the same. That knowledge of what it takes to mass produce a product has transcended generations, keeping the Central Massachusetts manufacturing industry alive.

Now, it’s not uncommon for entry-level factory workers to earn a living wage – and then some – of well over $50,000.

“This is a good industry where you can make money and have other opportunities,” Murray said.

John Killam, president and CEO of the Massachusetts Manufacturing Extension Partnership (MassMEP), said the region is now known for making specialty items rather than the major hubs of auto manufacturers in rust belt states Michigan and Indiana.

Because of that, Central Massachusetts factories are evolving and shedding that image of a dirty, dangerous factory floor.

“People who work in manufacturing are seeing the evolving landscape in terms of cleaner facilities, brighter facilities and a more collaborative manufacturing management group,” Killam said.

Now, manufacturers prioritize careers, growth, safety, equality and technology. That includes a step toward industry 4.0 and the digital world, said Killam.

Factories are becoming more digital with autonomous equipment and machines measuring performance, and those jobs will require skills that younger generations are born into.

“We’ll need technically oriented people who have a real feel for the technical side of making things, building things and using automation and robots,” Killam said.

The quick, personal dessert

Few products are as iconic to Worcester and Central Massachusetts as Table Talk Pies.

If you’ve ever stepped foot in a grocery store and wandered over to the baked goods section, you’ve probably seen a snack-sized Table Talk pie, because the company sells its pies at nearly every major supermarket in New England and beyond. Table Talk has withstood the test of time and has been making fresh baked pies since 1924. Table Talk’s four-inch snack pies are a New England staple, with flavors like apple, cherry, chocolate éclair, lemon, blueberry, peach, pecan, pineapple, pumpkin, sweet potato and wild blueberry.

Baked pies cool on a spiral cooling tower before they are boxed.

Table Talk continues to pump pies out of its Central Massachusetts factories to the tune of 240 million four-inch snack pies a year, according to the company’s 2019 numbers. Now, Table Talk makes about four million pies a week, said President Harry Kokkinis.

Table Talk continues to grow in popularity, and the company’s pies can now be found in California, Oregon, Arizona and parts of the Midwest. That demand for its pies is leading to several new factories, including a 50,000-square-foot factory on Southgate Street opened in 2017, a cold storage freezer opened in 2019 and an upcoming 140,000-square-foot factory in Worcester’s Main South neighborhood.

The sound you hear at stadiums

What starts with imported Baltic Birch plywood ends with a professional-grade loudspeaker capable of performing on some of the biggest stages.

Professional grade speakers ready for a stadium tour.

These loudspeakers from Whitinsville-based loudspeaker manufacturer Fulcrum Acoustics are bi-amplified two-way, high sensitivity arrayable coaxial horn systems designed for acoustically challenging spaces and where high acoustic output and fidelity is necessary.

The speaker can function on its own, in a distributed audio system, in a vertical installation or horizontally for use in horizontal tight-packed speaker arrays. These speakers have been used in gymnasiums, football fields, and in Hong Kong’s Times Square.

Aside from those uses, Fulcrum Acoustics designs and manufacturers audio equipment for use in hospitality, houses of worship, concert venues, theme parks, sports stadiums and more. The company’s speakers can be found at sports venues like McLane Stadium at Baylor University in Texas and the Chesapeake Energy Arena in Oklahoma City; hospitality venues like Laugh Boston, The Encore at Wynn Las Vegas; and concert halls like the Dallas City Performance hall and New England Conservatory of Music.

A 10,000-capacity stadium

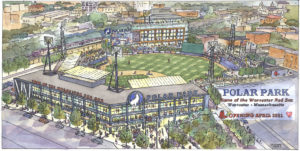

The $132 million ballpark will be the home of the Worcester Red Sox, the top minor league affiliate of the Boston Red Sox after the team said in 2018 it was moving to Worcester from Pawtucket.

The future home of the Worcester Red Sox.

Scheduled to open in April, the ballpark will have about 6,000 fixed seats and capacity for about 10,000 fans. The site is actually on land formerly owned by Wyman-Gordon, now a Houston, Texas-based manufacturer of forged metal components for the aerospace industry.

The ballpark will be one of the most technically advanced minor parks, featuring innovative technology like artificial intelligence in a proposed market in left field to allow customers to shop and pay without scanning or waiting in line.

The ballpark itself will sit on about six acres of land, but that won’t be the only land touched. In addition to the ballpark, a private developer is working with the city to develop a larger parcel across the street to include hotels, restaurants, apartments, retail and other use. The project also calls for improvements or reconstructions of several roads, the construction of a new road and the redevelopment of Kelley Square.

The world’s No. 3 seltzer

If you’ve ever needed a refreshing beverage on a hot summer day, look no further than Polar Seltzer.

Everybody’s favorite Black Cherry flavored Polar Seltzer.

Polar Beverages has been making its widely popular Polar Seltzer since the late 1800s and continues to innovate, releasing new flavors each year. The company also makes other drinks, like Sparkling Polar Dry, Sparkling

Water Frost, Seltzer’ade and other mixers, but Polar Seltzer is the company’s bread and butter.

Out of the company’s factories in Worcester and elsewhere, Polar makes 19 flavors of seltzers, including black cherry, blueberry lemonade, cherry pomegranate, cranberry clementine, cranberry lime, lemon, lime, mandarin, orange vanilla, original, pineapple pomelo, pomegranate, raspberry lime, ruby red grapefruit, toasted coconut, triple berry and vanilla.

The company’s constant innovation has propelled it to become the third largest seltzer company in the U.S. behind LaCroix and Pepsi’s Bubly. The company in 2020 signed a long-term franchise agreement with Keurig Dr Pepper to take Polar to a national distribution. President and CEO Ralph Crowley said Polar now makes other products under the Keurig Dr Pepper family, like Snapple, 7 Up, Sunkist and A&W Root Beer.

Top secrets crusher

At governmental agencies operating in top-secret environments, protecting information and data and making sure state secrets don’t fall into the wrong hands is critical. Now that most information is digital these days, agencies like the FBI, CIA, military and others need to make sure unused and obsolete devices can’t be mined for intelligence. That’s where Security Engineered Machining comes in.

Destroying hard drives, one wire at a time.

The company, based in Westborough, makes devices like the Model 0101 Automatic Hard Drive Crusher to physically destroy hard drives, regardless of size or whether they come from laptops, desktops or servers.

The crusher meets the National Security Agency and U.S. Department of Defense standards for the physical damage of media, so it’s used by government agencies, the defense industry and other highly secretive organizations placing a premium on information security.

At the touch of a button, the crusher delivers 12,000 pounds of force to destroy the hard drive and its internal platter – all within eight seconds. It can destroy up to four standard laptop drives of six ultra-thin laptop drives in one cycle. The company also makes devices to crush, shred, incinerate or otherwise destroy paper, CDs, DVDs, flash drives and virtually any other medium on which data is stored.

Presidential horseshoes

If there’s one company displaying the resilience of the manufacturing industry in Central Massachusetts, it might be St. Pierre Manufacturing Corp., one of the premier makers of equipment for yard games like bocce and horseshoes. The company – which turns 100 this year – evolved from a forging company making chains, wire rope, and materials for the military during times of war to a company specializing in summer fun.

Game of horse shoes.

The company’s horseshoes have graced the White House lawn on several occasions, as George H.W. Bush was an avid horseshoe player. According to Peter St. Pierre, vice president of finance and operations, the late Bush even had a horseshoe pit made at the White House so he could play when other politicians and heads of state came to visit.

The company manufactures several different professional quality horseshoe and bocce sets at its Worcester facility. Horseshoes are forged of solid steel and coated with a special non-slip finish. Bocce sets are made of high quality, solid resin with no filler material. Some sets have even been designed by professional horseshoe and bocce players and are used in tournaments and leagues.