Away from the shop floor, non-production employees find their own way to make a mark on the manufacturing industry

If you’re a young person embarking on a career today, an array of job options awaits. Perhaps you will heed an inner call to be a web developer, physician assistant, data analyst or massage therapist.

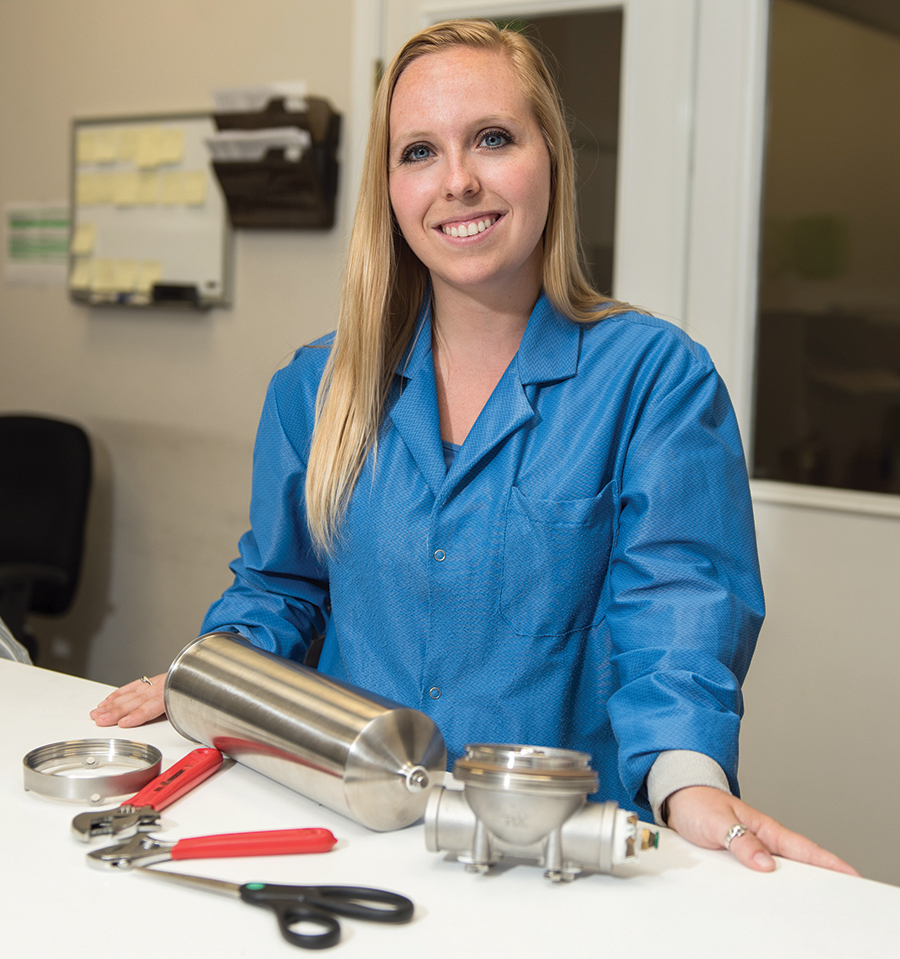

Sarah Lambert, 22

MSAT process engineer

Lonza Biologics, Portsmouth

Makes: Biopharmaceutical products Lives: Auburn

Education: Bachelor’s degree

Salary range for her job: $57,000-67,000

Or maybe you’d like to establish yourself in the world of manufacturing.

The idea of a job in the manufacturing field typically conjures images of workers wearing earplugs while surrounded by hulking machines on shop floors. Arguably, floor workers are the heart of any manufacturing organization. But there is a spectrum of other, perhaps less obvious, jobs in manufacturing just as vital to the success of the company.

Problem-solving on the fly

Sarah Lambert, 22, was always interested in science as she grew up, but her A-Ha moment came during an undergraduate class in biomanufactur-ing.

“That’s where I learned about the biotech field,” Lambert says. “Once I took that class I was like,

‘That’s exactly what I want to do.’”

And so today Lambert works as an MSAT pro-cess engineer (MSAT stands for manufacturing sci-ence and technology). In her position at Lonza Biologics in Portsmouth, she interacts with nearly every department in the company, which enables her to see how people across the organization ulti-mately contribute to making Lonza’s finished bio-pharmaceutical products.

Lambert also interacts with Lonza customers, and puts her bachelor’s degree in chemical engi-neering to good use when she provides solutions for workers who run into problems on the manu-facturing floor.

“We problem-solve to figure out what’s going wrong, and how to fix it while remaining compli-ant,” with the U.S. Food & Drug Administration and other regulatory agency requirements, she says.

Filtering your apple juice

Similarly, Elaina Lavigne, 24, has found much to like in her job as a lab technician at Critical Process Filtration, Inc., in Nashua. Lavigne is responsible for testing the company’s manufactured mem-branes, which act as filters.

“I’ve always had an interest in science in general,” Lavigne says, “[but] I didn’t want to be tied down to one specific field.”

Elaina Lavigne, 24

Laboratory technician

Critical Process Filtration, Inc., Nashua

Makes: Membrane and filtration systems

Lives: Hooksett

Education: Bachelor’s degree

Salary for her type of position: Around $40,000

She had no desire to be in a job that involved tedious, monotonous work. Her position at Critical Process Filtration, she says, “turned out to be pretty much exactly what I was interested in.”

Working for a manufacturer serving the bio-pharmaceutical, pharmaceutical, and food and beverage industries requires applying science to everyday products, Lavigne says. She sees how her labors and those of her co-workers benefit every consumer.

“I see it in everything we eat, drink, or any med-ication we’ve ever taken — it’s all been filtered in some way,” she said. “It’s neat to know that my apple juice was filtered and my vitamins were filtered, and stuff like that.”

Contrary to the common assumption working in a manufacturing company means being near greasy machinery, Lambert says her workplace is spotless.

“Since Lonza is a biopharmaceutical manufac-turer, all of our facilities where the manufacturing takes place are very, very clean,” she says

In fact, she says, ceilings and floors were designed with rounded edges and are made of special material to enable easier maintenance of an ultra-clean environment.

And despite the notion working in manufactur-ing means performing repetitive tasks, that clearly is not always the case.

The membranes manufactured at Critical Process Filtration, Lavigne says, “are all made dif-ferently, they’re all tested differently, and they all have to meet different criteria.” Even after a year and a half on the job, she says, “I learn something new every day here.”

Marketing the taste

Stephanie Kellogg, an associate brand manager at Stonyfield in Londonderry, got her first taste, so to speak, of working at Stonyfield as an intern. She realized her own mistaken assumption about manu-facturing when she was surprised to see that the company’s office and plant share the same address.

“I thought that the plant and the office team were going to be super-segregated and isolated from each other, but that was one thing I’ve noticed since working is how integrated everybody is,” Kellogg said.

Stephanie Kellogg, 22

Associate brand manager

Stonyfield Farm, Londonderry

Markets: Yogurt

Lives: Somerville, Mass.

Education: Bachelor’s degree

Salary range for her job: $60,000-80,000

The cross-functional interaction makes her happy – and more effective in her job.

“It’s really cool to be able to be so close to the product,” Kellogg says. “When we’re thinking about creating new flavors, or running new prod-ucts, we have to think about how the plant can implement this, and being so close to the plant makes it a lot easier” to know what is feasible. “I personally have talked to people in the plant and I understand how lines work.”

Kellogg enjoys the diversity of her work activities. “It’s a mix of all different types of marketing between packaging, programming, analytics, and research on just trying to make our product better for the consumer,” she says. “It’s so varied and . . . involves so much more than just sitting behind a computer” and looking at marketing-related data.

Meaningful work

Kellogg is grateful for the support and genuine relationships she shares with co-workers at Stonyfield.

“We all have to work together,” she says, “which I think is fun. And you’d think that the yogurt world isn’t that fast-paced, but it kind of is.”

But just as importantly, Kellogg feels that her work is meaningful.

“I always had a fascination for marketing,” she says, and for understanding what drives decisions. “I wanted to . . . feel like overall I’m changing the world for the better,” and Stonyfield’s mission dovetails nicely with that goal.

Likewise, Lambert likes to know that she is helping people through her work at biopharma-ceutical producer Lonza.

“You get to deliver to a lot of people a product that they really need,” she says, “which I always try to keep in the back of my head.”

Lambert sees a future filled with job possibili-ties and advancement for herself and others like her.

“There’s a lot more that goes into manufactur-ing than just making the parts. You have people in quality assurance and quality control . . . and all the supporting roles [such as] investigators and internal auditors. There are a lot of different paths you can take from where you start out,” she says.

People might think working in the manufactur-ing industry “is boring because [they imagine] you’re doing the same thing over and over again,” Lambert says. But in her experience, “the environ-ment is very fast-paced and there is always some-thing new to consider.

“I think,” Lambert says, “it’s a really great career path to follow.”