Researchers at Worcester Polytechnic Institute announced recently that they have developed a form of concrete that will fix its own cracks.

Using an enzyme found in red blood cells, they posit the new product is four times more durable than traditional concrete, and published their work in the journal Applied Materials Today.

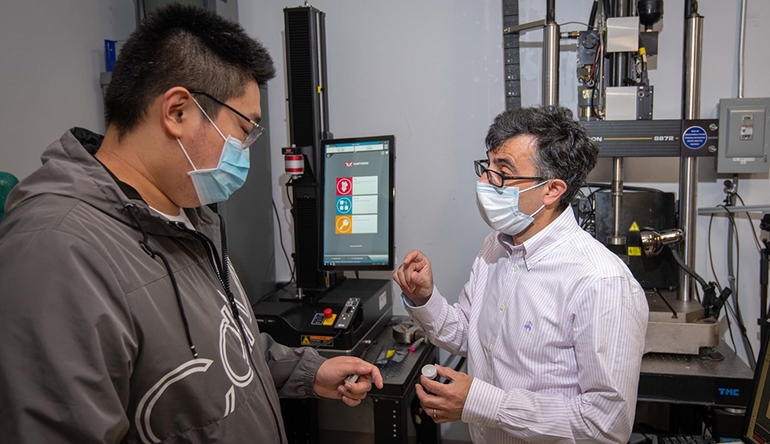

“If tiny cracks could automatically be repaired when they first start, they won’t turn into bigger problems that need repair or replacement,” said Nima Rahbar, associate professor of civil and environmental engineering and lead author on the paper, in a press release. “It sounds sci-fi, but it’s a real solution to a significant problem in the construction industry.”

According to the research, the enzyme used in the material automatically reacts with atmospheric carbon dioxide to create calcium carbonate crystals, which mimic concrete in structure and strength, and can fill cracks before larger problems develop. The process can reportedly heal millimeter-scale cracks within 24 hours.

The research team has developed three different ways to repair and manage concrete: a concrete mix to be built into a structure, which will then repair small cracks on its own; a mixture to induce self-healing in larger cracks; and a process to be applied to traditional concrete to repair cracks.

“Healing traditional concrete that’s already in use is critically beneficial, too, and will help reduce the need to produce and ship additional concrete, which has a huge environmental impact,” said Rahbar.

Rahbar has already patented the process, according to WPI.